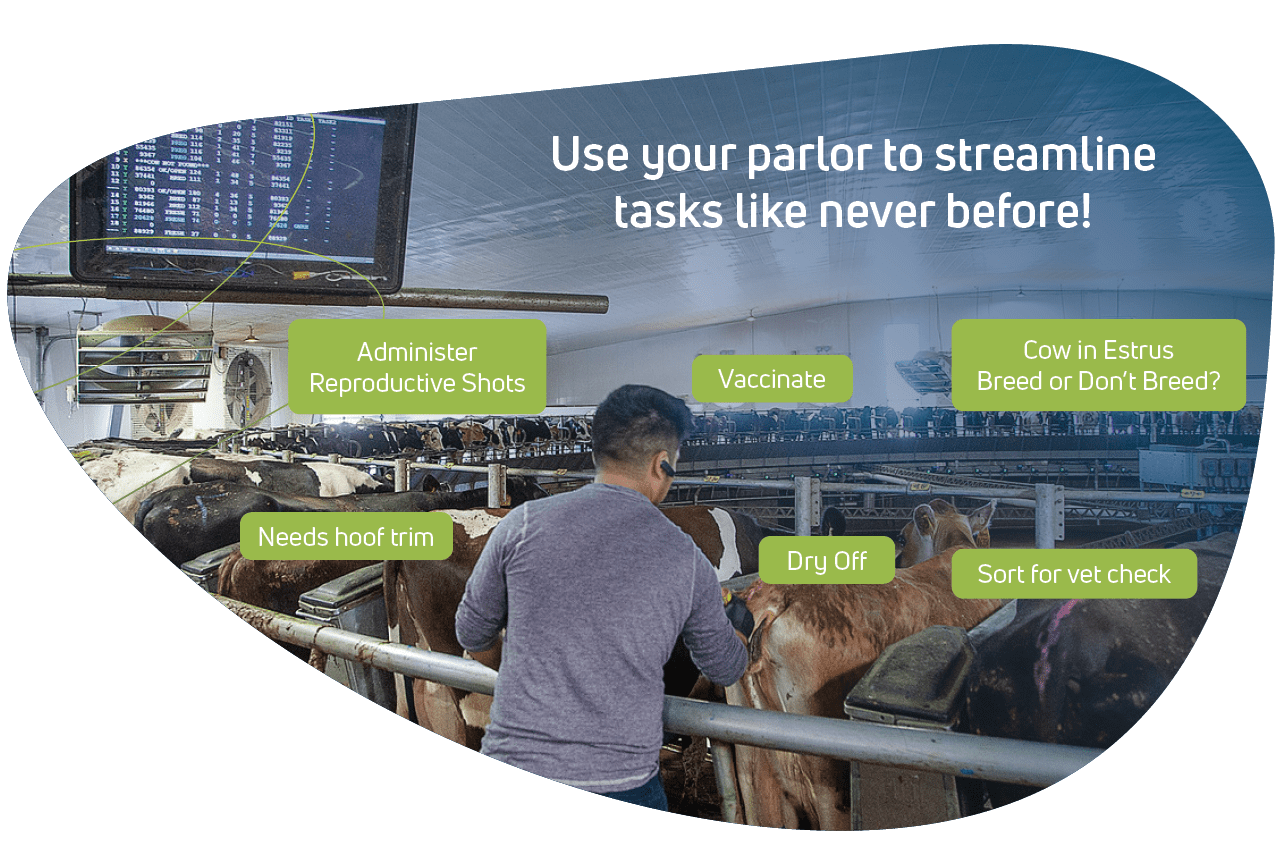

Wisconsin’s Ziegler Dairy Farm has seen significant improvements in performance since installing the ParlorBoss system in April 2021. As featured in Dairy Star, the Zieglers are better utilizing cows’ time in the parlor to complete tasks that previously kept the herd on their feet in the freestall barn.

Instead of spending hours trying to find cows that need reproductive shots, the Zieglers now give shots on the rotary. By giving shots in a more efficient manner, compliance improved by nearly 8% and the farm’s pregnancy rate climbed 9% all while reducing the amount of time cows spend in headlocks.

“It’s an awesome system,” Steve Ziegler said. “Anything we need to do with the cows, we can now do while they’re milking.”

The Ziegler family milks 1,070 cows and farms 3,500 acres near Middleton. Three generations work side by side on Ziegler Dairy Farm, which was founded in 1862. Ziegler and his four brothers – Andrew, Matt, Dan and Jon – are the fifth generation on the farm they operate with their parents, Greg and Cheryl, and grandparents, Leo and Carol Ziegler.

Cows are milked three times a day in the farm’s 48-stall rotary parlor that was installed in 2000.

A 70-inch TV screen hangs on the wall near the exit of the parlor, clearly showing which cows need shots or need to be sorted for trimming or other activities.

The new parlor technology is helping the Zieglers manage their herd more efficiently. A color-coded system makes it easy to identify groups of cows. For example, open cows are listed in red, fresh cows are light green, pregnant cows are dark green and trim cows are yellow.

“The system’s capabilities are endless,” Ziegler said. “Anything you want to do, you can add – somatic cell counts, milk weights, days in milk. If a cow has a high cell count, she’s going to stick out like a sore thumb, making decision making super easy.”

“The system’s capabilities are endless... Anything you want to do, you can add – somatic cell counts, milk weights, days in milk. If a cow has a high cell count, she’s going to stick out like a sore thumb, making decision making super easy.”

Steve Ziegler, Ziegler Dairy Farm

The system lists tasks for each cow, and shots are color coded as well with Lutalyse denoted as red and GnRH as blue, etc. Designed for rotary parlors, the technology works in cooperation with DairyComp herd management software.

Implementation of the system created a circle of success, touching many facets of the dairy operation. The family saved time and labor and increased its pregnancy rate.

In addition, cow comfort improved when they reduced the amount of time cows are locked up for reproductive protocols. Ziegler said the system has saved 10 hours per week in lockups.

“It shaved off so much time,” he said. “I know we gained milk and have less hoof issues because of that.”

With no way to efficiently sort, pregnant cows were locked up as well.

“We had to walk five pens to find the cows that needed shots,” Ziegler said. “It was a long time from the start of milking to the end – about three hours – and it took 45 minutes to give shots. All pens would be locked up this entire time. Pregnant cows shouldn’t have to be locked up because their neighbor needs a shot.”

A cow’s data is now displayed on the wall, making it painless to sort, Ziegler said.

“The process is efficient, and cow sorting became instantaneous,” he said. “You can see the last 18 cows at once of the 48-stall rotary. When you’re standing at the end, you know which cows are coming. The guy on the end post dips and gives shots.”

Pregnant cows are green; therefore, when glancing up at the screen, it is easy to tell if there is a cow that does not belong. The farm was able to eliminate one person in the parlor when it abandoned its manual sorting process.

“It’s really hard to keep groups separate on a rotary because it mixes cows so easily,” Ziegler said. “If a cow is not done milking when it’s time to get off, we’ll put a rope on her and let her go around again. She ends up in another group then.”

Previously, the Zieglers lived a data nightmare. Information about each cow was sent to 48 individual smart boxes, creating an intricate system prone to failure.

“There were lots of wires, and they were exposed to moisture,” Ziegler said. “On sort day, there could be up to six computers not working. The system was old and failing, and we didn’t want to put money into it. It was a headache. We were getting by, but we didn’t realize how bad it was until we got ParlorBoss.”

Now, one enclosed cable runs from Ziegler’s computer to the TV screen in the parlor. A hard-wired reader on each stall reads the cow’s RFID tag in her ear – a tag that has been with the animal since birth. The farm does not use an activity monitoring system.

“When we bought the technology, we just needed to add a TV in the parlor, so we took our mom’s from her living room and put all the data on one screen,” Ziegler said. “We did later replace Mom’s TV.”

Before installing the technology, the Zieglers’ pregnancy rate was around 25%. “It was good, but we wanted it to be better,” Ziegler said.

Fifteen years ago, the farm’s pregnancy rate hovered at 17%. They switched breeding companies and it climbed to 25% but then sat stagnant until they changed their strategy for how repro shots were given. Now, their pregnancy rate is at 34%.

Due to the ease of giving shots in the parlor, the Zieglers improved shot compliance and were able to advance to a double ovsynch program – two important factors that helped increase their pregnancy rate.

Prior to this, they did a presynch program with cherry picking. Ziegler and his brother, Jon, did the best they could when giving shots but inevitably missed 7% to 10% of cows due for repro shots. That number has since dropped to 1% or 2%.

“There was no system for us to go back and find the cows we missed,” Ziegler said. “We could only allow so much time for two guys to do it with fieldwork and other things we had to do. Timing was another factor. We probably were not giving shots at all the right times.”

Saturday is breeding day, and herd health is done every other Wednesday. Ziegler said those are the only days cows are locked up with 1.5 hours being the longest time any cow spends in a headlock.

“We did a minimum shot program before for repro because it reduced lockup time,” Ziegler said. “We were told we could up our breeding rate and increase our pregnancy rate if we increased the number of shots we were giving. We spend more money on shots now, but we’re breeding cows fewer times.”

Improving their pregnancy rate also helped the Zieglers boost the beef side of their operation. The family raises about 500 steers and breeds many animals to Angus.

“We can either sell those calves between day 1 and 4 or raise them to fill our steer barn,” Ziegler said. “By keeping a higher, tighter pregnancy rate, we’re confident in getting calves, so the majority come out black. As a result, we have more overflow calves to sell, which means more income.”

The ability to streamline tasks in the parlor has helped the Zieglers capture efficiencies across the farm, resulting in an all-around win for the dairy.

“ParlorBoss solved an important problem we had with data,” Ziegler said. “Now, you can see the data, and everyone is happy. There is no downside to the system. It’s super simple to use, and everything lines up perfectly. I love it.”

Written by Stacey Smart, published by DairyStar

Additional ParlorBoss Resources

About ParlorBoss

Learn more about the ParlorBoss and how it integrates with your DairyComp software.

Read: ParlorBoss Testimonial

See how Wisconsin's largest family-owned dairy reduced lockup times and scaled its operations with ParlorBoss.

WATCH: ParlorBoss Testimonial

See how ParlorBoss helps drive better efficiency and employee welfare.